클라우드 환경에서 이루어지는 유지보수

유지보수 작업의 간격을 모니터링하고, 현재 데이터를 기반으로 가능한 한 신속하게 구성요소를 교체하려면 어떻게 하는가? 유지보수 관련 문서가 전부 종이 서류로만 존재하면 유지보수 작업이 지루할 수 있다. 미래에는 유지보수 문서화도 디지털로 이루어져야 한다. EPLAN eVIEW와 Heitec의 HeiMAX 간의 인터페이스는 클라우드에서 서비스 및 유지보수를 더욱 신속하고 개선된 디지털 방식으로 수행하도록 지원한다. 하노버 박람회(Hannover Messe)의 EPLAN 및 Heitec 쇼케이스에서 더 많은 정보를 얻고 향후 실질적인 이슈에 대해 문의할 수 있다.

Showcase in Hanover: EPLAN eVIEW and HeiMAX

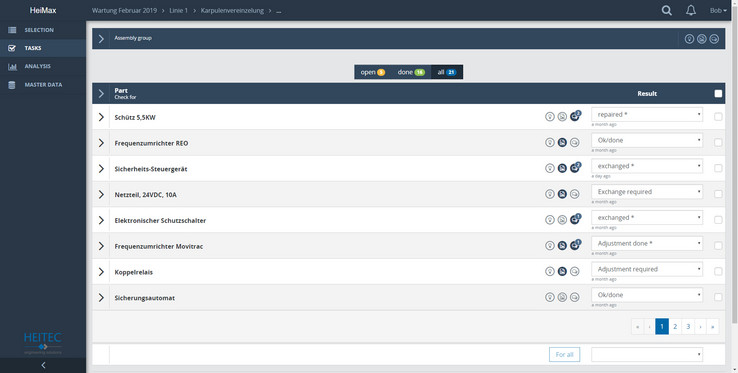

Monitoring maintenance intervals, switching out a component and doing it as quickly as possible based on current data? This can sometimes be tedious when the maintenance documentation only exists as a paper copy. But the future is digital: An interface between EPLAN eVIEW and HeiMAX from Heitec shows how service and maintenance intervals can be made faster, better and digital in the cloud. Anyone interested in finding out more can visit the showcase at the EPLAN or the Heitec stand at the Hannover Messe and also discuss future practical requirements. Monheim/Hanover, Germany, 01 April 2019 – Cloud applications offer a variety of new possibilities. These possibilities can be extensive when one cog interlocks with the next across disciplines. Or, in more concrete terms regarding the EPLAN and Heitec example, when engineering and maintenance “talk to one another”. The showcase of an interface between EPLAN eVIEW, a new cloud-based tool, and HeiMAX, a mobile maintenance assistant, makes the coming smart factory technology understandable in Hanover. How does it all work? EPLAN eVIEW provides a structure parts list that is transferred to HeiMAX. When maintenance is required, the service technicians can jump directly to the appropriate component in the schematics. If, for example, the servicing requires viewing the circuit logic, EPLAN eVIEW provides this data. The best thing about it: the use of EPLAN eVIEW, for which users in Hanover can register free of charge on the basis of the cloud system EPLAN ePulse, is all that is needed. No traditional EPLAN license is required to view the project. It is simply made available in the cloud and, as an example, switching out components can be commented on using the EPLAN eVIEW redlining function. This provides numerous tangible benefits for maintenance technicians and system operators: Component data from the EPLAN documentation, which are recorded in the wiring diagrams or parts lists, do not need to be entered manually any longer. They are centrally imported from the EPLAN eVIEW data model into the HeiMAX application. This means a digital workflow replaces documentation on paper, which too often remains the state of the art today. In the event of a malfunction, for instance, the service technicians can jump directly to the component in the schematic that is causing the problem. The entire original electrical engineering documentation created in EPLAN Electric P8 can be immediately viewed in EPLAN eVIEW. All information about the component is available in mere seconds.

Background

Maintenance checklists are often only available in paper form, not in a digital version. In many cases, maintenance documentation is also incomplete – which makes defining and adjusting maintenance intervals very complicated. The mobile maintenance assistant HeiMAX puts an end to such cumbersome processes. It can be used either in the cloud or as an offline version via a web server installation. All available data for maintenance of machines and plants are centrally coordinated in HeiMAX. This considerably accelerates service and maintenance and provides 100 per cent digital data. ©EPLAN Software & Service GmvbH & CO. KG, April 2019

More

- <link file:53430 download file>Download press kit

- <link>More on EPLAN eVIEW